Handling unit management

Tack the movements of groups of individual materials, by tracking the handling units that contain them.

Object structure

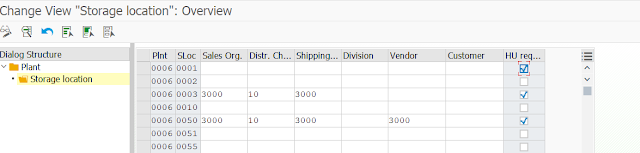

HU storage location

The handling unit in a HU Storage location means that there is control over the packed units, in other words, the system controls the inventory.

When a storage location is HU-managed, each stock transfer creates a delivery from one storage location to another. If the HU-managed storage location is the receiving storage location, the system creates an inbound delivery. If the HU-managed storage location is the issuing storage location, the system creates an outbound delivery. Subsequent processing in WM is controlled, as up to now, using transfer orders for the delivery.

If both storage locations are HU-managed, the handling units are copied into the inbound delivery and can be put away there also.

If, at the time of the stock transfer, both storage locations have HU and WM management, stock transfers can only be made using the two-step procedure. Therefore, as a rule, all stock transfers should take place using the two-step procedure.

Requirement 1

Packaging information is included in EDI message to allow the ship-to party to post goods receipt with reference to handling units.For that, the supplier must identify the handling units by using a sticker or label ( a material tag ).

The following five fields have been included in table VEKP:

If you use various packaging material types, but only within your plant, identification assignment via number range interval should be sufficient. If the packaging materials of these packaging material types are also shipped to customers, number assignment via an SSCC18 is the better choice.

Maintain the HU type for the SSCC18 number assignment for each packaging material type, even if automatic number assignment occurs via a number range interval.

Logistics - General > Handling Unit Management > External Identification > SSCC Generation Acc. to EAN128 > Maintain SSCC Generation for Each Plant / Storage Location

Logistics - General > Handling Unit Management > External Identification > SSCC Generation Acc. to EAN128 > Maintain SSCC Generation for Each Warehouse Number

The international location numbers (ILN) are issued by the national subsidiaries of EAN International (for example, the UCC in USA or the CCG (Office for Coorganization) in Germany). It contains 13 digits. The base number is the first seven numbers of ILN type 2 which acts as a basis for issuing the SSCC and material EAN usage.

The ILN base number that you enter in this customizing is used to generate the SSCC (and HU number). You can also use the basis number that you used to issue the material EAN. If you want to use another number or you don't have an ILN, you should apply for one with one of the organizations named above.

You can extend the base number as much as you require if you want to represent the SSCC number in your company structure. However, if you use an extended basis number, you can then only use fewer other numbers. You will need to shorten the date category of the number range by the number of digits you extended the base number with.

Maintain an entry down to the Storage location or warehouse number level and then re-test.

Because of the rescheduling, the dates, which are managed in the delivery header, are adjusted based on the existing scheduling master data. The automatic adjustment in accordance with the stored master data can be unwanted in special cases.

This note prevents the rescheduling of the delivery during the creation of new delivery items without reference to a predecessor (these are, among other things, packing items).

350462 - Rescheduling when packing for a delivery

This note must not be implemented if the packaging material items are relevant for requirements. Not rescheduling the delivery can result in termination in the demand planning because of the missing material staging date in the packaging material items (see note 191123).

Install the correction instructions Ensure that the item category used for the packaging materials has the item type C.

- Handling unit management

- Handling unit

- Object structure

- HU storage location

- HU Main Operations

- Packing instruction

- Pack at a Packing Station

- Packing material

- Handling Unit Management Within Logistics

- Quality Inspection for Handling Units

- Physical Inventory of Handling Units

- Serial Numbers in Handling Units

- Generation of Delivery Items for Packaging Materials

- Packaging material is subject to batch management requirement

- Automotive functions

- Outbound Delivery of Handling Units

- Picking from WM According to Packing Instruction ( HU-managed WM storage location )

- Material Tag

- Handling unit with WM ? ( to be added )

- Configuration

- Handling Unit Supplements

- Packaging Material Types

- Maintain Goods Movements for Handling Unit Stock-Posting

- Delivery

- Materials management

- Additional information

- Scheduling for a packing material

- 2819578 - Handling Unit person data (Driver, Country, etc)

- 2749821 - Handling unit dimensions are not updated from idoc

- 2665255 - ILN Basic number errors while creating Handling Unit

- 2167876 - SPED - HUFUNCTIONS 034

- 2167012 - VL02N - Batch split - Batch number not transferred to the HU

- 2926186 - How to carry out a handling unit inventory correctly?

- 1655683 - Not possible to create a HU with BAPI_HU_CREATE in a HUM location

- 2176859 - Unable to process Handling Unit Output Type

Handling unit management

Handling unit

See a handling unit as a physical unit that consists of a combination of materials and packaging materials. All the information contained in the material items, such as batches and serial numbers, is available in the handling units.If HUs are used in a cross-system supply chain, they have to be numbered according to a specific pattern to comply with the requirement of unique identification. The HUs can be assigned an SSCC number. (!) Each handling unit has a unique identification number, which is typically printed as a barcode on a material tag.

Object structure

- VEKP table (Handling Unit - Header Table)

- VEPO table (Packing: Handling Unit Item (Contents))

- HUSTAT statuses

- VEVW Where-Used List for Handling Units

- HUINV_HDR Handling Unit: Phys. Inv. Document Header

- HUINV_ITEM Handling Unit: Physical Inventory Document Item

- HUINV_SERNR Handling Unit Phys. Inv. Doc. – Serial Numbers for Item

- HUMSEG Reference-HU-Item for Material Doc.Item that was Posted Last

- HUMSEG_SER Serial Numbers for the HUMSEG Table

The handling unit in a HU Storage location means that there is control over the packed units, in other words, the system controls the inventory.

When a storage location is HU-managed, each stock transfer creates a delivery from one storage location to another. If the HU-managed storage location is the receiving storage location, the system creates an inbound delivery. If the HU-managed storage location is the issuing storage location, the system creates an outbound delivery. Subsequent processing in WM is controlled, as up to now, using transfer orders for the delivery.

If both storage locations are HU-managed, the handling units are copied into the inbound delivery and can be put away there also.

If, at the time of the stock transfer, both storage locations have HU and WM management, stock transfers can only be made using the two-step procedure. Therefore, as a rule, all stock transfers should take place using the two-step procedure.

SM30 + V_T001L_L (field: V_T001L_L-LGORT)

SPRO > Logistics - General > Handling Unit Management > Basics > Materials Management > Inventory Management > HU Requirement for Storage Locations and Default Values for Deliveries

This dialog was created mainly for the user that physically packs materials at a packing station in the warehouse. It supports both keyboard entries and scanned entries (assuming the necessary information is available in barcode format). You can also use a scale that is connected to the system to transmit the exact weight to the SAP System.

Use the Set Profile for Packing Station IMG activity to set a packing station profile for each computer so that you can configure the packing process differently for individual packing stations.

From the SAP menu, select Logistics Central Functions Handling Unit Management Goods Movement of Handling Units Posting General Goods Movements (with HU).

This is especially important if you:

Delivery items are generated if at least one of the following two requirements is fulfilled.

SPRO > Logistics - General > Handling Unit Management > Basics > Materials Management > Inventory Management > HU Requirement for Storage Locations and Default Values for Deliveries

HU Main Operations

Transactions for creating and changing handling units:

- Create/Change/Repack Handling Units (General) (HU02);

- Packing Station in Warehouse (HUPAST);

- Pack Production Orders (COPAWA/COWBPACK);

- Using the Handling Unit Monitor (HUMO);

- VLMOVE transaction is then used for the movements possible for any handling unit and the packing/unpacking can be done through the delivery transactions (inbound/outbound).

Display functions for handling units:

- Directly using the Handling Unit Monitor (HUMO);

- Indirectly using the stock overviews for the material (MMBE and LS26);

- For the individual document types: Inbound and outbound delivery, transfers, material documents, and so on (HUIBD, HUOBD, HUTRA, and so on).

Packing instruction

Specify the material and the quantity to be packed in certain packaging ( a handling unit ) automatically according to requirements.

A packing instruction is a template for a new handling unit. Features

- Using one packing instruction for several materials ( a reference packing instruction in the material master )

- Single/ Multi-level packing instructions ( nested HU-s )

- Items not relevant for HU ( a material is only relevant for packing information / Text Item in a Packing Instruction )

- Handling unit status management

- Packing Instruction Determination

For each delivery type, you can define whether the automatic packing function is to be called up during delivery creation.

The delivery interface makes it possible to pack deliveries by using external systems. IDoc segments:

- E1EDL37 Handling unit header

- E1EDL44 Handling unit item

- E1EDL54 Repacking handling units

Customizing

- Packing Control: Logistics Execution >Shipping>Packing> Packing control by item category.

- The connection between “material to pack” and “packaging material”: Logistics Execution >Shipping>Packing> Define Packing Material Types.

- Logistics Execution >Shipping>Packing> Define Material group for Packaging Material.

- Logistics Execution >Shipping>Packing> Define Allowed Packaging Material.

- Logistics General > Handling Unit management > External Identification > SSCC Generation Acc. to EAN 128

Automatic packing also supports PACKMODI enhancement.

Pack at a Packing Station (HUPAST)

For the most part, the general packing dialog is used by packing specialists that are not involved in the physical packing process. The packing station dialog is another way of creating and processing both handling units linked to deliveries and handling units without document reference.This dialog was created mainly for the user that physically packs materials at a packing station in the warehouse. It supports both keyboard entries and scanned entries (assuming the necessary information is available in barcode format). You can also use a scale that is connected to the system to transmit the exact weight to the SAP System.

Use the Set Profile for Packing Station IMG activity to set a packing station profile for each computer so that you can configure the packing process differently for individual packing stations.

The packing station allows you to reflect material packing in the system. This function offers you the following options:

- Creating and changing handling units with reference to a delivery (inbound and outbound delivery): You can record in the system what quantities of which delivery items are packed in a handling unit.

- Creating handling units without object reference: This options lets you pack materials (in handling units) that you want to return to the warehouse (put away), for example.

- Printing labels for individual handling units: When a handling unit is completely packed, you can immediately print a label that includes its handling unit number, for example.

- Updating the handling unit’s weight: If existing handling units are weighed, the packing station uses a connection to an external scale to offer you an easy way of updating a handling unit’s total weight.

Packing material

- Material Group: Packaging Materials

- Groups together materials that require similar packaging materials.

- Packaging Material Type

- The packaging material type that you enter here is linked in Customizing to a material group for packaging materials, which you assign to a material in the material master. As you assemble the handling unit, you call up a list of packaging materials that are allowed for an item that you want to pack. This system puts together this list by matching the material group for packaging materials for that item with the appropriate packaging material types.

- Allowed packaging weight

- Maximum weight of other materials that are packed in this packaging material.

- Allowed packaging volume

- Maximum volume of other materials that are packed in this packaging material.

- Maximum level (by volume)

- Enter the extent to which the packaging material can be filled as a percentage.

- This field is used for informational purposes only.

- Stacking factor

- Specifies how many pallets, for example, can be stacked on top of one another. At present, this value is purely for information purposes.

- Excess Weight Tolerance for Handling unit

- Specifies the tolerance limit for exceeding the maximum weight allowed for a particular packaging material during packing.

- The tolerance limit is taken into consideration if you use the Pack material and New HU per part. qty of matrl functions for packing. The tolerance limit is not used in combination with the New HU if full function.

- Excess Volume Tolerance of the Handling Unit

- Specifies the tolerance limit for the maximum packing volume allowed for a particular packaging material.

- The maximum packing volume allowed by the system is the maximum packing volume plus the tolerance for the following functions: Pack material, Pack HUs, New HU per part. qty of matrl. Tolerance is not included in the New HU if the full function

- Packaging Material is Closed Packaging

- For closed packaging materials, the total volume is not increased by the loading volume of the contents.

- The total volume of a box is the same whether it is full or empty, which makes it a closed packaging material.

- The total volume of a pallet, however, is figured from the tare weight of the pallet itself plus the volume of the goods packed on it. Therefore, pallets are open packaging materials.

Handling Unit Management Within Logistics

- Sales and Distribution: ... a special agreement with the customer as to the packaging in which this material is to be delivered, we can reflect this agreement by using existing (or creating) packing instructions

- Goods receipt: The shipping notification generates an inbound delivery that includes the packing information from the shipping notification

- Quality Management:

- If the packing data is known in the inbound delivery, an inspection lot is created for these handling units.

- If the handling units have been put away in HU-managed storage locations, the handling units can be re-transferred.

- As soon as the quality inspection is complete, the stock in the handling units is posted to unrestricted-use stock or to scrap materials, depending on the usage decision.

- If the status of the handling unit changes from planned to implemented (or changes during the creation of implemented handling units from production), an inspection lot is created for the handling units.

- Warehouse Management

- Handling units with raw materials are provided in time for production in accordance with the production requirement.

- If the production storage location is HU-managed, the goods issue takes place either after the successful staging of the materials or through the explicit specification of the handling unit.

- Transfer orders are created for the materials to be delivered and the handling units are picked from stock.

- Shipping

- The handling units that were picked can be repacked in the delivery.

- If there is a packaging proposal in the sales order, the delivery can be packed automatically in accordance with this proposal.

- Goods issue is posted for the handling units.

Packing for Inbound and Outbound Deliveries

https://help.sap.com/viewer/248c3cdd7e6548999a7f5b95118f4522/6.17.17/en-US/8e7cbd534f22b44ce10000000a174cb4.htmlHandling Units in Production Orders

Handling Units in Process Manufacturing

Handling Units in the Warehouse

Handling Units in Inventory Management

Goods Movements with Handling Units

We can use this new function to post goods movements for handling units (HUs) without object reference by entering handling units directly.From the SAP menu, select Logistics Central Functions Handling Unit Management Goods Movement of Handling Units Posting General Goods Movements (with HU).

Quality Inspection for Handling Units

If you use the Quality Management (QM) component, you can perform quality inspections on handling units(HU) in Handling Unit Management at delivery item level. Inspection lots can also be automatically created, when the corresponding delivery item is packed. These inspection lots are then created by the system with reference to the HU and always contain a current reference to the assigned HUs.

The quantities in inspection stock are managed directly using the HU and not using the inspection lot. This means that during goods movements the currently assigned HUs are determined using the inspection lot and can be transferred

In order to inspect handling units in QM, the following prerequisites must be fulfilled:

The quantities in inspection stock are managed directly using the HU and not using the inspection lot. This means that during goods movements the currently assigned HUs are determined using the inspection lot and can be transferred

In order to inspect handling units in QM, the following prerequisites must be fulfilled:

- In Customizing for Handling Unit Management ( Inventory Management ), the respective movement type is not deactivated for quality inspections. The indicator QM not active is not set.

- In the material master record of the material for the HU, the corresponding inspection type is created and activated under Inspection Setup , and the indicator Inspection for HU and, if necessary, the indicator Post to inspection stock is set.

Events:

Packing in the inbound delivery (goods receipts for purchase orders) | 01 |

Packing of finished product from production | 04 |

Packing of other goods movements (for example, outbound deliveries) | 05 |

Packing for stock transfers | 08 |

Physical Inventory of Handling Units

Handling unit inventory was designed for the purposes of physical inventory in HU-managed storage locations where conventional inventory management is not possible.Serial Numbers in Handling Units

In order to use serial numbers in handling units, the following prerequisites must be met:

- A serial number profile must have been created with the serialization procedure HUSL in Customizing for Serial Number Management.

- We also recommend that you set the stock check indicator for this serial number profile. This has the effect that when the handling unit is at an HU-managed storage location, a serial number can only be moved with the assigned handling unit. This prevents use of the serial number in material documents that do not have any reference to the handling unit.

- The serial number profile that allows serialization in handling units must be entered in the appropriate material master record.

- If you are working with movement types, batches or configurable materials, the valuation type, batch and configuration must already have been defined at the time of the serial number assignment in the handling unit.

Generation of Delivery Items for Packaging Materials

It is possible to generate delivery items for the packaging materials from the handling units within delivery processing automatically. In order to have the weight of the HU added to the delivery total weight, it is necessary to have delivery items generated for the handling units.- Manage packaging materials in Inventory Management

- Pick packaging materials in the warehouse

- Charge customers for packaging materials

- Make packaging materials available to customers as returnable packaging

Use packaging-material item generation to bill packaging materials to customers or to maintain packaging materials in inventory management. SAP recommends that you only implement item generation in goods receipt and goods issue.

Customizing settings to achieve automatic item generation for packaging material

Notes:

Customizing settings to achieve automatic item generation for packaging material

- Transaction 0184: Customizing LE – Shipping – Deliveries – Define Item Category Determination

- This is the link between the Item Category Group of the Packaging Material (e.g. ‘VERP’) and the Delivery Type (e.g ‘LO’)

- Transaction VHAR: Customizing: LO – HU – BASICS – Define Packaging Material Types

- For the parameter ‘Plant determ.’ enter ‘A’ or ‘B’.

- In case you have chosen ‘ ‘ (blank) meaning ‘Plant is entered manually in the HU’ you need to enter the plant manually to the HU header at packing to have a chance to obtain the packaging material item.

- Transaction 0VLK: Customizing: LE – Shipping – Deliveries – Define Delivery Types

- In ‘DocumentContent’ activate the flag ‘Gen.Pack.Matl.Item

- In the Logistics Execution ® Shipping ® Delivery section, use the Define Item Category Determination in Deliveries activity to set up an item category assignment for the delivery type, an item category group for the packaging material, and make usage-indicator settings for PACK .

- For example, the system determines item category HUPM for item category group VERP in a sales order delivery.

Coding:

SAPLV51H FUNCTION HU_PACKING_DELIVERY

Line 369:

PERFORM positionen_generieren USING

is_delivery-tvlk_pmpos_gen ( delivery type settings )

it_xlips ( main item )

it_xvbup

LS_ISU_POSITIONEN_GENERIEREN

ls_object.

SAPLV51H FORM POSITIONEN_GENERIEREN

loop at IT_LIPS into LS_LIPS where VBELN = LF_DELIVERY and

POSAR = 'C' and

not UPDKZ = 'D'.

call function 'V51P_GENERATE_OBJECT_ITEMS'

exporting

IF_GENERATE = IF_GENERATE ( from the delivery type )

IS_OBJECT = IS_OBJECT

changing

CT_GENPOS = LT_GENPOS

exceptions

FATAL_ERROR = 01

others = 99.

SAPLV51P FUNCTION V51P_GENERATE_OBJECT_ITEMS

SAPLV51P FORM CREATE_DEL_ITEM_OLD

Read the HU header from the IDoc segment.

IF <header>-werks IS INITIAL OR <header>-pstyv IS INITIAL.

CHECK NOT <header>-kzpgn IS INITIAL AND

NOT if_generate IS INITIAL.

ENDIF.

MOVE-CORRESPONDING <header> TO ls_510.

SAPFV50P FORM POSITION_GENERIEREN_HU

positionsgenerieren = 'X'.

PERFORM lips-matnr_pruefen(sapfv50p) USING lf_subrc.

IF NOT lf_subrc IS INITIAL.

CLEAR: cf_posnr, positionsgenerieren.

v50agl-sammelgang = lf_sammelgang.

EXIT.

ENDIF.

PERFORM lips_fuellen_or(sapfv50p) CHANGING lf_subrc.

SAPFV50P FORM LIPS_FUELLEN_OR

if productselection ne charx or

not lips-uecha is initial.

perform lips-pstyv_ermitteln using lf_vwpos.

endif.

CALL FUNCTION 'RV_LIPS_PSTYV_DETERMINE'

IF lips-uecha IS INITIAL AND sy-subrc <> 0.

CASE sy-subrc.

WHEN 1.

SET CURSOR FIELD 'LIPS-PSTYV' LINE sy-stepl.

PERFORM message_handling(sapmv50a) USING cvbap-posnr

'320'

'E'

'VL'

likp-lfart

maapv-mtpos

lpe_vwpos

lips-pstyv.

WHEN 2.

SET CURSOR FIELD 'LIPS-PSTYV' LINE sy-stepl.

PERFORM message_handling(sapmv50a) USING cvbap-posnr

'321'

'E'

'VL'

lips-pstyv

space

space

space.

ENDCASE.

IF lips-pstyv IS INITIAL. "hp_215365

CLEAR: cf_posnr, positionsgenerieren.

v50agl-sammelgang = lf_sammelgang.

EXIT.

ENDIF.

Useful FM-s:

CALL FUNCTION 'V51P_FILL_GT'

CALL FUNCTION 'V51S_CREATE_HU_HEADER'

LV51SU04/VEKP_FUELLEN_MARA

cs_vekp-vhilm = mara-matnr.

cs_vekp-laeng = marm-laeng.

cs_vekp-breit = marm-breit.

cs_vekp-hoehe = marm-hoehe.

cs_vekp-meabm = marm-meabm.

cs_vekp-gewto = mara-gewto.

cs_vekp-volto = mara-volto.

cs_vekp-magrv = mara-magrv.

cs_vekp-vhart = mara-vhart.

cs_vekp-kzgvh = mara-kzgvh.

cs_vekp-meins = mara-meins.

cs_vekp-mtpos = mara-mtpos_mara.

* Füllen Eigengewicht/Eigenvolumen aus MARM oder MARA

IF NOT marm-brgew IS INITIAL.

cs_vekp-tarag = marm-brgew.

cs_vekp-gewei = marm-gewei.

ELSE.

cs_vekp-tarag = mara-brgew.

cs_vekp-gewei = mara-gewei.

ENDIF.

IF NOT marm-volum IS INITIAL.

cs_vekp-tavol = marm-volum.

cs_vekp-voleh = marm-voleh.

ELSE.

cs_vekp-tavol = mara-volum.

cs_vekp-voleh = mara-voleh.

ENDIF.

- VEKP-WERKS is only filled at HU creation in case this is triggered by the packaging material type customizing settings or if the HU is created by IDOC.

- Influencing VEKP-WERKS and VEKP-LGORT values are possible in BADI HU_MAIN, method header_update_in_packing.

Delivery items are generated if at least one of the following two requirements is fulfilled.

Requirement 1

- an Item Category is assigned to the HU header and

- Plant is defined for the HU header

- an Item Category is assigned to the HU header and

- the flag for item generation in the delivery type is set and

- the flag for item generation in the packaging material type is set.

Following table is the summary for release 46C and higher:

| Item Category Determination | Plant determination | Flag 'Generation of Delivery Items for HU | Indicator 'Generate Delivery Items' for packaging material types | Additional delivery item |

| No item category determined | 'blank - Plant is entered manually in the handling unit' / 'A - Plant proposed from the packaging material' / 'B - Plant determined from the plant where first item was packed' | Checked / Not checked | Blank / 'A - Item generation if ship-to party is unique' / 'B - Item generation in first packed delivery' | No |

| Item category determined | 'B - Plant determined from the plant where first item was packed' | Checked / Not checked | Blank / 'A - Item generation if ship-to party is unique' / 'B - Item generation in first packed delivery' | Yes |

| Item category determined | 'blank - Plant is entered manually in the handling unit' / 'A - Plant proposed from the packaging material' | Checked | Blank | No |

| Item category determined | 'blank - Plant is entered manually in the handling unit' / 'A - Plant proposed from the packaging material' | Checked | 'A - Item generation if ship-to party is unique' / 'B - Item generation in first packed delivery' | Yes |

| Item category determined | 'blank - Plant is entered manually in the handling unit' / 'A - Plant proposed from the packaging material' | Not checked | Blank / 'A - Item generation if ship-to party is unique' / 'B - Item generation in first packed delivery' | No |

1452388 - Packing in a delivery creates a new line item

- The material packing type is configured in customising to generate a new line item when the material is packed.

- Goto customising menu path: SPRO -> Logistics General -> Handling Unit Management -> Basics -> Define Packaging Material Types

- Select the packaging material type used and click on the details button

- Field "GenerateDlvItms" has been maintained with either 'A' or 'B'

- In addition, the customizing in transaction 0184 contains an item category for packing assigned to the delivery type (IMG Menu Path: Logistics Execution -> Shipping -> Deliveries -> Define Item Category Usage in Deliveries)/ For example, the below entry contains item category VERP which causes a new line item to be created in the delivery:

DlvT ItCG USE ItmC ItmC MltC MltC MltC LF VERP PACK LDN DLN TAN LNN

Resolution

- In HU customizing, remove the flag to generate a delivery item for the packing material.

- In transaction 0184 remove the line entry containing VERP.

Picking by SHPCON ( delivery item generation for a packing material)

if the picking is done by an inbound IDoc and a packing material has the attribute to generate an item, the error will be recorded even if we have no entry to determine the item cat. type for a delivery item ( requirement #1 ). In the dialog mode, the error message is displayed in the log and can be suppressed.

The packing material type in the IDOC is not relevant if it is inbound

Packaging material is subject to batch management requirement

In deliveries, the system generates a packaging material item for each batch. The relevant item category is determined on the basis of the charge indicator in the sales order item. The batch to be delivered is available in the packed batch split item as the characteristic value.

Packaging material is not subject to batch management requirement

The system generates one packing item per delivery for each packaging material and charge indicator in the sales order item. The packaging materials are available in the corresponding characteristics of the batches to be delivered.

Automotive functions

Outbound Delivery of Handling Units

Process overview

- A planner monitors the documents that are due for delivery and creates outbound deliveries;

- Handling units have already been created in production and assigned to the customer requirements;

- The planner assigns HU-s to deliveries.

In shipping, we can assign handling units to an existing SD shipment via radio frequency

- Scan the shipment, and then the desired handling units.

- The system analyzes the content of the HUs and

- Creates deliveries for them which are automatically assigned to the shipment.

Picking from WM According to Packing Instruction ( HU-managed WM storage location )

- Two ship-to-parties receive the same material, which is packed according to different packing instructions. When creating deliveries and the transfer orders, we can define that only HUs which have been formed according to the packing instruction are put into the delivery.

Material Tag

The new message type MALB (material label) is defined for handling units to print a single material tag for the handling unit.

Configuration

HU: External number range

We can only ensure that the identification number is unique system-wide if you assign an SSCC18.- To ensure a unique number assignment, select the Set Unique Number Assignment for HU Identification activity and set the HU ID unique indicator.

- To set the type of number assignment, choose the Define Number Assignment for Each Packaging Material Type activity.

- To set number assignment for HU identification by using a number range interval, choose the Number Range Maintenance for HU Identification activity.

- If you want to ensure a unique identification system-wide, use the activities in the SSCC Generation Acc. to the EAN128 section.

Packaging Material Types

The packaging material type combines packaging materials into groups and contains essential control features which apply to the corresponding shipping materials. When you specify a shipping material type in the material master record, each shipping material is assigned to a shipping material type.Handling Unit Supplements

In the handling unit table, you will find five reserve fields that are not assigned to specific functions and that you can fill and use installation-specificallyThe following five fields have been included in table VEKP:

- VEGR1 (handling unit group 1)

- VEGR2 (handling unit group 2)

- VEGR3 (handling unit group 3)

- VEGR4 (handling unit group 4)

- VEGR5 (handling unit group 5)

Maintain Goods Movements for Handling Unit Stock-Posting

Then it is accessed in HUMO transaction, edit:

Materials Management

HU Requirement for Storage Locations and Default Values for Deliveries

Delivery

- Packing Control By Item Category

- Define Requirements for Packing in the Delivery

Number Assignment for Each Packaging Material Type

A handling unit is a technical system reflection of a physical object. For this reason, it is logical to assign each handling unit a unique number. A number range object can guarantee that all number of assignments are unique within one client. A unique number assignment is only possible throughout the entire system via assignment of an SSCC18.If you use various packaging material types, but only within your plant, identification assignment via number range interval should be sufficient. If the packaging materials of these packaging material types are also shipped to customers, number assignment via an SSCC18 is the better choice.

Maintain the HU type for the SSCC18 number assignment for each packaging material type, even if automatic number assignment occurs via a number range interval.

Development

Useful

2176859 - Unable to process Handling Unit Output Type

Once delivery has been Goods Issued, use tCode VL74 to reprocess the Handling Unit Output types instead of VL02n or HU02.1655683 - Not possible to create a HU with BAPI_HU_CREATE in a HUM location

The storage location specified is a HUM storage location and BAPI_HU_CREATE cannot accept the storage location entered.

When processing HU creation in foreground (Transaction HU02), the process is carried out in two steps:

Creation of HU in non-HUM storage location.

Transfer of HU to a HUM storage location.

In background, the design of the BAPI is to provide the creation only (one step).

Resolution

Use BAPI_HU_CREATE to create a HU in non HUM storage location.

Once created, foreground processing is required to move the HU to the HUM storage location.

2926186 - How to carry out a handling unit inventory correctly?

Reproducing the Issue

1. Create a handling unit inventory via transaction HUINV01

2. Select the handling unit(s) in HUINV01

- click on the save button or press Ctrl+S

- the system creates the inventory document

- the inventory number can be seen at the bottom of the screen

3. Change or delete the inventory document in HUINV02 if any changes made on the document please save it with pressing the 'Save' button or Ctrl+S

4. Count the handling unit stock in HUINV03

- the user can decide first if the handling unit exists or not with using the 'HU Exists' or 'HU does not exist' button

- it's important to choose any of these buttons because later on HUINV05 won't allow the clearing and the following message will come: No postable items were found

- the user can increase or decrease the counted quantity or it can be set automatically to zero with the 'Zero Count' button

- in both cases the 'Counted' flag is set automatically, it shows to the user if the item has already been counted

- the count can be saved with the 'Save' button or pressing Ctrl+S

- re-count is possible, run again HUINV03 and do the necessary steps

5. Check the difference in HUINV04

- it shows the details coming from the difference counting

6. Write off the difference in HUINV05

- the previously selected button ('HU Exists' or 'HU does not exist') is being marked on the screen, it helps to the user to double check

- 'Counted' is also being marked

- mark the item and click on 'Clear Items' or press F9

- the system saves the data automatically and inactivates the INIV status and activates INVE

7. Remove the INVE status in HUINV06

- the inventory process finishes with removing the INVE status

- highlight the handling unit and click on 'Save' or use Ctrl+S

- if the handling unit doesn't have the active INVE status then the following error comes: No handling units found with the required criteria Message No. VHU01103

- in this case please check the HUSSTAT table and do the necessary step, see more information at the 'Resolution' part

Cause

The handling unit inventory was created to be able to count nested handling units. The handling unit inventory sets various statuses during the inventory process and these are blocking the document to be corrupted and preventing inconsistencies.

Resolution

1. After creating the inventory, the system activates the INIV status on the handling unit, so that cannot be changed/modified until the last step of the inventory.

2. After the user clears the differences via HUINV05, the system removes automatically the active INIV status and sets INVE status. This one can be removed via the transaction HUINV06. After this step the HU can be used again.

3. The statuses can be check in transaction BS23:

- INIV status - I0539

- INVE status - I0540

4. If the user immediately deletes the inventory document after the creation in HUINV02, then the system removes the INIV status automatically and makes the handling unit available again. These statuses can be checked in HUSSTAT database tables, please copy the handling unit internal number from the header table (VEKP-VENUM) of the handling unit and open the HUSSTAT database table. The handling unit number should be copied via leading zeros then please extend this number with HU characters like: HU + 000000001 > then insert this number to the OBJNR field like: HU000000001

5. The INACT column shows which statuses are activated on the handling unit, it helps to the user to find the upcoming step to remove or change the status. These statuses can be seen also in HUMO transaction after opening the HU and go to 'Status' tab. The system status row shows the currently active statuses.

6. REMARK: the handling unit inventory can be carried out on a handling unit managed storage location. Please check in database table T001L if the field XHUPF has the 'X' value for the plant and storage location combination. If the handling unit management hasn't been activated for the storage location then the inventory document creation fails with the following error in HUINV01: Plant &1 storage location &2 is not managed using HUs HUINV008

7. The handling unit management can be set on the following path for the storage location: SPRO > Logistics General > Handling Unit Management > Basics > Material Management > Inventory Management > HU Requirement for Storage Locations and Default Values for Deliveries

2167012 - VL02N - Batch split - Batch number not transferred to the HU

Reproducing the Issue

- create delivery in VL01n with automatic packing

- change the storage location of the delivery item from a non HU, non WM managed stotrage location to a WM, but no HU managed storage location

- create and confirm transfer order with batch information

- batch numbers are transferred from the transfer order to the delivery batch split items

- go to the packing screen of the delivery

- the HUs do not contain the batch information

Cause

- First of all there is NO BACKWARD LINK from the delivery item BACK to the packing information. When the delivery item is updated there are NEVER changes triggered in the existing packing structure. Therefore in this case the batches will not be transfered into the HUs.

Furthermore if you have the field "packaging according to batch item" (TVLP-CHHPV) set, then the system pack the accumulated quantity in the batch main item without batch information.

Resolution

- clear TVLP-CHHPV in the transaction 0VLP for the relevant item category

- repacking of the delivery with the batch information will then be possible in the transaction VL02n (after the TO creation and confirmation with the batch information)

2167876 - SPED - HUFUNCTIONS 034

Adjust your customising settings: The HU number assigned to the outbound delivery must be in the external number range interval defined for the packaging material type

1. check which packaging material is used: go to vl02n - packing screen - packaging materials

2. check which packaging material type is assigned to the packaging material: Go to MM03 - Sales:general/plant view - Packaging material data - Packaging mat. type

3. check which external number range interval is assigned to the packaging material type: go to transaction VHAR - select the packaging material type - details

4. check the number range interval: go to transaction SNRO - object: HU_VEKP - display - ranges - intervals

5. he HU number used must be between the lower and the upper limit of the interval defined in step 3

A)

Create a new number range interval for external HU numbers (Transaction SNRO or IMG activity: Logistics General -> Handling Unit Management -> External Identification -> Number Range Maintenance for HU Identification -> Edit Intervals). This new interval should cover the number range interval which is not yet covered

Assign this new number range interval as external number range interval to the packaging material type which is used for your packaging material. (IMG: Logistics General -> Handling Unit Management -> Define Number Assignment for Each Packaging Material Type

B)

Alternatively, you could change the limits of the external interval used to meet the requirement as of point 5 (IMG activity: Logistics General -> Handling Unit Management -> External Identification -> Number Range Maintenance for HU Identification -> Edit Intervals)

2665255 - ILN Basic number errors while creating Handling Unit

Check the ILN basis number customizing that has been maintained either at plant/storage location level or warehouse number level in the Implementation Guide:Logistics - General > Handling Unit Management > External Identification > SSCC Generation Acc. to EAN128 > Maintain SSCC Generation for Each Plant / Storage Location

Logistics - General > Handling Unit Management > External Identification > SSCC Generation Acc. to EAN128 > Maintain SSCC Generation for Each Warehouse Number

The international location numbers (ILN) are issued by the national subsidiaries of EAN International (for example, the UCC in USA or the CCG (Office for Coorganization) in Germany). It contains 13 digits. The base number is the first seven numbers of ILN type 2 which acts as a basis for issuing the SSCC and material EAN usage.

The ILN base number that you enter in this customizing is used to generate the SSCC (and HU number). You can also use the basis number that you used to issue the material EAN. If you want to use another number or you don't have an ILN, you should apply for one with one of the organizations named above.

You can extend the base number as much as you require if you want to represent the SSCC number in your company structure. However, if you use an extended basis number, you can then only use fewer other numbers. You will need to shorten the date category of the number range by the number of digits you extended the base number with.

Maintain an entry down to the Storage location or warehouse number level and then re-test.

2749821 - Handling unit dimensions are not updated from idoc

The length, width and height are not maintained within packing via an idoc.- These information is coming from material master of the packaging material itself.

- All checks and packing functionality is carried out using the weight and volume.

2819578 - Handling Unit person data (Driver, Country, etc)

The 'packaging material category' (from the packaging material type customizing) dictates the availability of these fields. For example, in handling units with a packaging material category of 'means of transport', it dictates that additional fields, such as Driver and Alternate driver are available for input.

- SPRO (IMG) -> Logistics - General > Handling Unit Management > Basics > Define Packaging Material Types>> Packaging Material Category

- Here, you can set the packaging material category to 'Means of Transport'

- This will open up those additional required fields

Scheduling for a packing item

191123 - Missing MBDAT in packaging delivery itemsThe material availability date (MBDAT) is empty for the packing items generated in the delivery. If this item is relevant for requirements, the requirements updated when saving the delivery also have an empty MBDAT = 00.00.0000. In the requirements/stock overview (Transaction MD04), the date of the MRP element is missing. This can cause a planning run (MRP run) to terminate with the error message 61060 (MRP) 'The date 00.00.0000 is not convertible'.

483407 - Packing items not to be scheduled in deliveries

When you process delivery notes, a rescheduling is carried out if packing items are created. This is an SAP standard function. This rescheduling is in particular necessary for receiving correct scheduling data for the new item, in particular for materials planning. Without scheduling, no material availability date would be available for the new delivery item. This would result in terminations in materials planning (MRP run).Because of the rescheduling, the dates, which are managed in the delivery header, are adjusted based on the existing scheduling master data. The automatic adjustment in accordance with the stored master data can be unwanted in special cases.

This note prevents the rescheduling of the delivery during the creation of new delivery items without reference to a predecessor (these are, among other things, packing items).

350462 - Rescheduling when packing for a delivery

This note must not be implemented if the packaging material items are relevant for requirements. Not rescheduling the delivery can result in termination in the demand planning because of the missing material staging date in the packaging material items (see note 191123).

Install the correction instructions Ensure that the item category used for the packaging materials has the item type C.

2790937 - Storage location not determined automatically for packing material in Outbound Delivery

Item Category is not Customized for Storage Location- Run transaction VL02N for the relevant Outbound delivery

- Check the Item Category for the packaging material line item

- Run transaction 0VLP or go to customizing in SPRO -> Logistics Execution -> Shipping -> Deliveries -> Define Item Categories for Deliveries, for the relevant Item Category

- Select the option 'Determine SLoc' under Warehouse Control and Packing

Other

- https://blogs.sap.com/2017/09/08/automatic-delivery-items-generation-for-packaging-materials-of-picking-unit-sd-wm-hu-interface/

- 2323180 – Delivery items for packaging materials of picking unit

- 831204 – Delivery items for packaging materials

- 1534664 – HU restrictions when reversing movement for STO deliveries.

Comments

Post a Comment