Procurement

- Introduction

- Procurement and Purchasing. What is the difference?

- Procurement processes

- RFQ Management Process

- Direct / Indirect procurement

- Stakeholder management

- Strategic sourcing

- RFQ

- 1104434 - FAQ: Request for Quotation

- Purchase order

- 491211 - FAQ: Purchase order (general)

- Release strategy

- 1991355 - How Incoterms filled into Purchase Order (header / item)

- Account Assignment category

- 496082 - FAQ: Account assignment in purchasing

- Confirmation

- 2695094 - What is the use of Confirmation Control Key 'CH' (= PO change) ?

- 2436023 - How is the confirmation control key determined in PO/STO?

- Price variance

- Scheduling Agreement

- References

- Scheduling Agreement Releases

- Material requirements planning

- Release generation (FRC/JIT)

- Creation Profile

- Output/Transmission of release

- Administer

- Cumulative Quantities

- Centrally agreed contract

- Processes

- Direct Source to Pay

- Procurement optimization

- Source Determination

- + Simplified Sourcing Approach (S4)

- Source Determination with SAP E-Sourcing On-Demand Solution

- Optimizing the Order Quantity

- Creating Purchase Orders with Source Determination

- Collecting purchase requisitions to a purchase order (ME59N)

- Control parameter determination

- Confirmation control key determination

- Normal PO items (not returns items)

- Returns PO items

- Version management

- Additional information

- 3048137 - How to make a PO editable or not based on its status when its completely approved?

- 772558 - FAQ: Quantity conversion and rounding

- 459350 - FAQ: Partner determination in purchasing

- SAP Note: 1360549 JIT/FDS: Incorrect last GR date in delivery schedule

- SAP Note: 1309001 Incorrect date for last goods receipt in sched. Agreement

- SAP Note: 1263278 ME84: No selection with MPR controller in MRP area

- 365604 - FAQ: Release strategies in purchasing

- 493900 - FAQ: Release Strategy

- 3012524 - Purchase order can be subject to release strategy even if all items are blocked (LOEKZ = S)

- 2497558 - Authorization checks in ME29N and ME54N

- 2974384 - What fields are checked for release strategy for PO's

- 1739381 - Multiple currencies in purchase order release strategy needed

- 2898923 - Release Strategy not reset while using version management

- 2783690 - Mass Reject option not available in ME28

- 2565597 - Release strategy not appearing in purchase order/ contract/ schedule agreement

- 1961482 - Reset release strategy when version number is set as Characteristic in Customizing

- 2616399 - Overall PR release strategy not triggered when EBAN-ERNAM is also the base of the rel. strat.

- 2087860 - ME175 - Release strategy cannot be canceled / updated after PO is printed

- 448814 - FAQ: Texts in Purchasing

- 459512 - FAQ: manufacturer part numbers (MPN) in purchasing

- 457497 - FAQ: Message processing in purchasing

- 664928 - FAQ: Version management

Introduction

Procurement and Purchasing. What is the difference?

Purchasing is a simple and concise term that will incorporate providing money for a product or goods. It can even be said that purchasing is a small and one of the aspects of procurement while Procurement has a broader sense and more strategic.

- Purchase Order (PO) Acknowledgment

- Advanced Notice of shipment

- Receipt of Goods

- Recording of Invoice

- Three-way matching

- Payment to the supplier

The steps involved in procurement are:

- Identification of the requirement

- Authorization of the Purchase Request

- Approval of the Purchase Request Procurement

- Identification of Vendors Inquiries or

- Receipt of the Quotation

- Negotiation of the contract Selection of the Supplier

- Purchase Order (PO) Acknowledgement

- Advanced Notice of Shipment

- Receipt of Goods Recording of Invoice

- Three-way matching

- Payment to the supplier

Procurement processes

- Forecast, plan requirements

- Requisition

- Supplier identification and selection

- Approval and contract generation

- Reciever materials and documents

- Settle and pay

- Measure performance

RFQ Management Process

The RFQ process is one of the most powerful processes a buyer can use to get price information from the supplier market. Every buyer should learn how to run an RFI and RFQ process effectively.

What’s the difference between RFQ and RFP?

An RFQ is used when you know exactly what you need, and you are only asking for the price and an RFP is used when the buyer has a problem, and he asks suppliers to come up with different solutions and identify the accompanying costs.RFQ process

The RFQ process can be divided into four steps: preparation, processing, awarding, and closing.

- Invitation and description: Here you should describe your company, the project, and any other necessary background information. Make sure the purpose of the RFQ is clearly laid out.

- General terms and conditions (GTC):Attaching the GTC or contract template gives bidders a framework to follow when they consider making a bid. State clearly which terms are negotiable and which are not. Clarity here will reduce negotiation time when it comes time to close the RFQ.

- Pricing template: It is very frustrating to try and compare quotes submitted in different formats and structures. By preparing a pricing template you give participants guidelines they must be following in order to submit a bid.

- Awarding selection criteria and weights: In order to keep the RFQ process transparent and easily understood by participants, you will need to describe the awarding criteria and weights you plan to use when selecting an RFQ winner.

It is good business to provide feedback to all participants, not only the winner. But even if you have selected a winner, do not announce the final decision before you have signed a contract.

Direct / Indirect procurement

Direct procurement

Direct categories are all goods purchased by the company which directly enter into the production process of that company. For the food industry as an example, ingredients and packaging will be the key direct procurement categories.

Indirect procurement

Indirect categories are all the goods and services that are bought by the company to enable its activity. This entails a wide scope, including marketing-related services (media buying, agencies), IT related services (hardware, software), HR-related services (recruitment agencies, training), facilities management, and office services (Telecoms, furniture, cleaning, catering, printers), or utilities (gas, electricity, water)...etc. Indirect procurement is the sourcing and purchasing of materials, goods, or services necessary for internal use.

Stakeholder management

- Understand your Stakeholder's requirements and use their terminology

- Profile your stakeholders

- Align procurement activity to their business needs.

- Add value by Demonstrating deep knowledge of their categories, suppliers, and markets and use that conversation to create Value.

- Start small and achieve Quick wins

- Face to face engagement

- Use of cross-functional teams

Strategic sourcing

Strategic sourcing refers to the process of identifying the spend profile of an organization and its supplier base to ensure their business requirements are aligned with the suppliers.

- Step 1 - Profile the Category

- Step 2 - Supply Market Analysis

- Step 3 - Develop the Strategy

- Step 4 - Select the Sourcing Process

- Step 5 - Negotiate

- Step 6 - Implement & Integrate

- Step 7 - Benchmark & Track Results

RFQ

1104434 - FAQ: Request for Quotation

Question:

Why the field "Account assignment category" (eban-knttp) in the selection criteria to create a request for quotation with reference to a purchase requisition is not considered and the system display a list independent of this selection parameter?

Answer:

For requests for quotations the account assignment type is not taken from the purchase requisition because from a business point of view a request for quotation is not assigned to an account.

Therefore the checks for account assignment are not carried out.

This was implemented with SAP Note 189182.

----------------------------------------

Question:

Why are Partners not determined when a RFQ was created via the Manage RFQ Fiori app?

Answer:

Currently there is NO partner determination implemented for the Fiori application. As a consequence the partners will not be determined when creating a Quotation out of the RFQ or a Purchase Order with reference to the Quotation. Only Bidders (Vendors) are saved as partner for the RFQ.

This have to be considered as 'Missing Functionality' in terms of SAP. Please refer to SAP Note 11.

----------------------------------------

Purchase requisition

Purchase Requisition Release Date

Specifies the date on which the purchase order should be initiated on the basis of the purchase requisition.

The release date is based on:

- The purchasing department processing time defined for the plant

- The planned delivery time from the material master record or purchasing info record

- The delivery date

- The goods receipt processing time from the material master record

Note, the system takes the planned delivery time from the purchasing info record and the GR processing time into account in the following cases:

- If the purchase requisition was triggered by materials planning or

- If the purchase requisition was created or changed manually and automatic source determination has been defined for it.

Example

Purch. dept Planned del. GR proc.

proc. time time time

|----------|---------------------|--------|

Release PO Delivery Requirement

date date date date

Requirement date: 10/1/2007

GR processing time: 2 days (working days)

Planned delivery time: 10 days (calendar days)

Purchasing dept processing time: 2 days (working days)

For the material to be available on the date it is needed, the purchase requisition must be released on 09/13/2007 (requirement date minus GR processing time, planned delivery time, and purchasing department processing time).

Purchase order

491211 - FAQ: Purchase order (general)

1. Question:

Why is the material short text not copied from the purchase requisition to the purchase order?

Answer:

The short text is only copied if the two documents have the same language.

--------------------------

2. Question:

Why is the material short text not displayed in the logon language in the purchase order even though it is stored in the logon language in the material master?

Answer:

When the purchase order is created, the short text is transferred in the document language and copied to the purchase order. Afterwards, the system displays this copied and possibly changed short text always in display mode regardless of the logon language.

--------------------------

3. Question:

You want to use transaction ME59 to convert a purchase requisition automatically into a purchase order. Why is the purchase requisition not selected?

Answer:

See Note 335079 and Note 786303.

--------------------------

4. Question:

A purchase order is created automatically from a purchase requisition using transaction ME59. According to which criteria is the document type of the purchase order determined?

Answer:

See Note 114213.

--------------------------

5. Question:

A purchase order is created automatically from a purchase requisition using transaction ME59. Why is the field selection not taken into account here?

Answer:

See Note 427854.

--------------------------

6. Question:

Why is the default value for the info update indicator not used in the purchase order in the parameter EVO?

Answer:

See Note 202173.

--------------------------

7. Question:

When you post purchase orders with many items, performance problems occur. How can the performance be improved?

Answer:

See Note 188837.

--------------------------

8. Question:

The batch field was set in Customizing as a required entry field. When you create a purchase order using transaction ME21, why does the system also issue message ME 083 "Enter a batch" for materials that are not flagged as subject to batch management requirement in the material master?

Answer:

See Note 410817.

--------------------------

9. Question:

Are the old purchase order transactions (ME21, ME22, ME23) still available in addition to the EnjoySAP transactions (ME21N, ME22N, ME23N)?

Answer:

See SAP Note 1803189.

--------------------------

10. Question:

Why is the purchase requisition not locked when creating a purchase order using transaction ME21, ME27, or ME57?

Answer:

The programs of the old purchase order are also used mass processing. Therefore, the purchase requisition is not locked for performance reasons. However, you can activate the purchase requisition lock using the customer enhancement MM06E011 (EXIT_SAPMM06E_024). . In addition, see Note 378335.

Alternatively, you can use transaction ME21N.

--------------------------

11. Question:

Why is the material description not taken from an existing reference document (for example, contract), when you create a purchase order (vendor unknown, ME25)?

Answer:

With the replacement of the old purchase order (ME21/ME25) for Release 4.6A, the default data logic was changed for the new transaction ME21N so that the short text from the purchase requisition has priority when you create purchase orders with reference to the purchase requisition, provided that both reference documents (contract or purchase requisition) have the same language.

With transaction ME25 (Create Purchase Order - Vendor unknown), purchase orders are always created using the intermediate document "Purchase Requisition". As a result, the material description comes from the item screen from transaction ME25.

--------------------------

12. Question:

How can I avoid creating purchase orders with reference to the deleted purchase requisition items?

Answer:

There are various solutions:

a) In the document overview, select the purchase requisition selection variant and add the deletion indicator to the sort criteria. The hierarchy in the selection list should be as follows:

1.Deletion indicator, 2. Purchase requisition, 3.Purchase requisition item, and so on

As a result, all purchase requisition items are assigned to two separate folders. You can then open the folder with the items you require (without deletion indicators) and select these directly to the purchase order.

b) You create a selection variant for all purchase requisition items without deletion indicator.

In the document overview, select the purchase requisitions selection variant. On the following selection window, you can use the dynamic selection pushbutton to specify additional selection criteria.

Choose the deletion indicator criterion from the purchase requisition folder and enter X. The system returns all purchase requisition items without deletion indicator.

c) You can use transaction OME0 to set warning message 06 050 as an error message.

--------------------------

13. Question:

Is it possible to create several purchase orders with reference to the same purchase requisition?

Answer:

Yes, this is possible. You can create up to 99 purchase orders in the R/3 standard system. If you want to avoid this system behavior, refer to Note 385002. If you create more than 99 purchase orders with reference to the same purchase requisition, a dump occurs in the function module ME_CREATE_DOCUMENT (ME 807: System error: error during insert in table RSDB).

--------------------------

14. Question:

Is it possible to change the plant when creating a purchase order withreference to a contract?

Answer:

No, in this case the system issues error message 06 730 informing you that the plant of the reference document and the plant do not match up.

--------------------------

15. Question:

During the creation of a purchase order with reference to a purchase requisition with different units, a part of the purchase requisition quantity remains open.

Answer:

This is not an error. Due to the rounding effect, this quantity remains open in the first case. You can set the completed indicator in the purchase requisition manually. In the second case, the system issues error message 06 076 "Materials of requisition xxx item xxx alr. ordered in full". You can therefore use various units in the purchase requisition and purchase order only if you set the error message as a warning.

--------------------------

16. Question:

You use transaction ME59. During execution, the system issues only error messages and no warning messages.

Answer:

This is the standard system design. In transaction ME59, the system issues only error messages and no warning messages. As of Release 4.70, transaction ME59N is available. When you execute this transaction, the system also displays all warning messages.

--------------------------

17. Question:

Why can I not change the currency in a purchase order?

Answer:

If you have already posted additional delivery costs, goods receipts, and so on with purchase order currency, you are no longer allowed to change the currency of a purchase order.

--------------------------

18. Question:

During the creation of a purchase order, the system issues error message ME 067: "GR indicators of item cat. & and account assignment cat. & incompatible".

Answer:

There are various reasons:

a) The good receipt non-valuated (binding) indicator is set for the item category in the purchasing document (see transaction OLME: "Define External Representation of Item Categories").

b) The good receipt non-valuated (binding) indicator is set for the account assignment category in the purchasing document (see transaction OLME: "Account Assignment -> Maintain Account Assignment Categories").

c) The goods receipt non-valuated indicators or the goods receipt indicators are set inconsistently for the item category and the account assignment category.

--------------------------

19. Question:

Are there any restrictions for the quantity conversion for batch items?

Answer:

Yes. In the old purchase order transactions (ME21, ME22), conversion factors were not taken into account for batch items. Note 1559176 describes and corrects this error.

Note that in the old purchase order transactions (ME21, ME22), the batch-specific conversion factors are no longer read again when batches are changed.

For this, use the new purchase order transactions (ME21N, ME22N).

--------------------------

Other Terms

Frequently asked question, FAQ, purchase order, ME21, ME22, ME23, ME21N, ME22N, ME23N, SAPMM06E, MEPO, ME57, ME58, ME59, RM06BB10, RM06BB20, T160, T161A, OMH5, OMEC, MEX_FELDAUSWAHL, field selection, OMF1, RM06BZ00, EVO, default value, OMFI, ZL02, SPINF, V_T160V-EINFB, EINFB, info record update, info record, purchasing info record, purchasing default value, T160V, T160V-EINFB, EVOPA, purchase order generation, performance, document type, PReq, purchase requisition, batch, PReq lock, purchase requisition lock, ME25, contract

Confirmation

2436023 - How is the confirmation control key determined in PO/STO?

The determination is done in include LMEPOF53. Note 794195 describes the logic to some extent. The full logic is:Normal PO items (not returns items)

If goods receipt is already posted for the PO item or if there are existing confirmation entries, the determination is not executed.

If the PO item is created by referencing another PO item (meaning an existing PO is copied), the confirmation control key (CCK) is simply copied from the referenced item.

If the PO item is not created by referencing another PO, but it has a reference to a contract, the system takes the CCK of the contract (even if the CCK is blank).

One exception is if the contract has the item category "material group" or "material unknown". In that case the CCK is taken over only if it is not blank.

If the PO is not created with reference to a contract, the system looks up in the info record. If one is found, the system takes the CCK from the info record.

If both a contract and an info record are referenced, the system always takes the CCK of the contract, even if it is blank.

If the PO has no contract and no info record, the system takes the CCK of the vendor master data (LFM1-BSTAE).

If there is alternative vendor master data (e.g. plants-specific, or vendor subrange in table LFM2), then the CCK is taken from there.

If the PO has a contract or info record reference, the CCK will be taken from those and not the vendor master even if it is blank in the contract / info record.

This behavior can be changed by implementing the modification note 909885 (bear in mind note 170183 before applying a modification). If you implement note 909885, the system will take the CCK from the vendor master if it is blank in the info record.

However, this note does not handle the situation if a contract is also used. This means that if the contract and the info record both have a blank CCK and the vendor master has a non-blank CCK, the system will still use the blank CCK from the contract and not the CCK from the vendor master.

If no info record and contract is used and the CCK is also blank in the vendor master, the system will check the table T163LV.

If the PO item has a storage location and there is an entry in T163LV with that document category/document type/plant/storage location, the CCK from the T163LV will be used.

If the PO item has a storage location and there is no entry in T163LV with that document category/document type/plant/storage location, the system will check for an entry with blank storage location (meaning only with the document category, document type and plant of the PO item). If an entry is found, it is used.

If the PO item has no storage location, the system checks if there is an entry in T163LV with the document category, document type and plant of the PO and with blank storage location. If there is an entry, it will be used.

If no CCK can be determined using this logic, the CCK will be left empty.

In ME21N, ME22N, ME59N, BAPI_PO_CREATE1 and BAPI_PO_CHANGE you can use BADI ME_PROCESS_PO_CUST to introduce your own logic and derive from the standard one.

Returns PO items

If goods receipt is already posted for the PO item or if there are existing confirmation entries, the determination is not executed.

The use of a CCK is generally not allowed in returns PO items. It is allowed only in a special case, if Advanced Returns Management is used (business function OPS_ADVRETURNS_1 is activated). If it is active and the Enhanced Store returns is also activated for the PO document type (T161-FLS_RSTO=X) and the PO has a supplying plant (EKKO-RESWK) or a vendor that is assigned to a plant (LFA1-WERKS is not blank), only then it is possible to use a CCK.

If these conditions are met, the system checks if the PO is created by referencing another PO for which the Enhanced Store returns is also active. If such a PO is used as reference, the CCK is taken over from that.

If no such PO is used, the system proceeds to read the T163LV for a CCK with the same logic as in case of non-returns items above.

In case of returns items, the contract, info record and vendor master are not checked, only the reference PO and the T163LV.

If no CCK is found based on T163LV, a manual entry is possible.

In ME21N, ME22N, ME59N, BAPI_PO_CREATE1 and BAPI_PO_CHANGE you can use BADI ME_PROCESS_PO_CUST to introduce your own logic and derive from the standard one.

Remark:

If you use Advanced Returns Management and create a replacement PO with transaction MSR_VRM_GR, the PO will always have the confirmation control key 0004. This is hardcoded in include LMSR_REP_DIALOG_GRP02.

For the document type in use, ensure that you had set the "Stock transfer: Take vendor data into account" flag ("Trfr Vdr" field in the customizing screen) in customizing. If a stock transport order or scheduling agreement is then created and a vendor is assigned to the supplying plant, the system adopts the data from the vendor master record. You can find the flag in the path: transaction OLME > Purchase Order > Define Document Types > select the document type.

2695094 - What is the use of Confirmation Control Key 'CH' (= PO change) ?

In SPEC2000 for a PO, if an inbound S1ORDEXC idoc comes from vendor side, it can come and update the PO quantity, price or other detail like delivery dates etc.

This change is identified in confirmations with T163D-EBTYP = CH. Confirmation Control Key 'CH' is linked to internal confirmation category '4'

Release strategy

To check the rel. strategy triggered in debugging mode, breakpoint could be placed when the subroutine STRATEGIE_CEKKO is called in program SAPLMEPO under Include MM06EF0S_STRATEGIE_ERMITTELN. It’s the function module ME_REL_STRATEGIE_EKKO (called just after the above subroutine) which returns the triggered rel. strategy, rel. group, rel. indicator, rel. status and if the PO has been completely released. Understanding this FM would greatly help in understanding the Purchase document rel. strategies. A good documentation of this FM by SAP too would have been great.BAPI that helps in release is: BAPI_PO_RELEASE which takes the purchase doc. Number and release code as mandatory parameters. Likewise to revoke the release, BAPI_PO_RESET_RELEASE could be used. The documentation of these BAPI’s explains the functionality beautifully.

Another useful BAPI that provides release information about a PO is BAPI_PO_GETRELINFO.

1991355 - How Incoterms filled into Purchase Order (header / item)

You can have incoterms (including INCO1 and INCO2) at header level and item level and these values can be different, they are independent from each other, and if you have more than one line item in the PO from a material, they could have different incoterms, as within the info records you can create incoterms specific to the purchase organization (no plant defined info records), and/or you can setup same or a different incoterms for different plants.But the incoterms could copied also from other reference documents, like PO, contract, RFQ.

Generally the incoterms can be copied from the following documents to purchase order HEADER level, listed in priority order, if one of the documents is given as reference, incoterms will be adopted (empty value also if allowed) and the rest will not be checked:

- Reference PO header (empty also will be adopted)

- Contract header (empty also will be adopted)

- RFQ header

- Vendor master (empty also will be adopted)

Overally the incoterms can be copied from the following documents to purchase order ITEM level, listed in priority order, if one of the documents is given as reference, incoterms will be adopted (empty value also if allowed) and the rest will not be checked:

- Reference PO item (empty also will be adopted)

- Quotation item if quotation exists for RFQ (empty also will be adopted)

- Contract item whose item category is not 4 (material unknown) nor 8 (material group) (empty also will be adopted) or

- Contract item whose item category is 4 or 8 but one of the incoterms fields (INCO1 or INCO2) is filled out

- Info Record (empty also will be adopted)

- RFQ item level (empty also will be adopted)

Account Assignment category

Specification of the objects (e.g. cost center, sales order, project) that are charged in the case of a purchase order for a material that is intended for direct usage or consumption.Multiple account assignment allows you to apportion the cost of a material covered by a PO among your own cost center and several others.

The account assignment category determines:

- The nature of the account assignment (cost center, sales order, and so on)

- Which accounts are to be charged when the incoming invoice or goods receipt is posted

- Which account assignment data you must provide

- SPRO > MM > Purchasing > Account Assignment > Define Combination of Item Categories/Account Assignment Categories > If you have created new account categories, you maintain the combinations for the item categories here.

- SPRO > MM > Purchasing > Account Assignment > Set Subscreen for Account Assignment (Coding) Block

Cat-s:

- Main asset number and sub-number

- Order and G/L account number

- Production order number

- Business process and G/L account number

- Cost center and G/L account number

- Sales order and G/L account number

- Project and G/L account number

- Unknown

496082 - FAQ: Account assignment in purchasing

1. Question:

Why is the G/L account for a sales order with non-valuated individual sales order stock different from the account with valuated individual sales order stock?

Answer:

See Note 458270.

--------------------------

2. Question:

Can you create several assets at the same time in the new purchasing transactions?

Answer:

You can create several assets at the same time. However, you must first ensure that at least as many account assignment lines have been created as the number of assets that you want to create. You can do this very easily using the copy function.

--------------------------

3. Question:

You create a purchase order with account assignment using transaction ME22. You enter a material group, from which a G/L account is determined using the valuation class. If you then switch to a material group that does not determine a G/L account via the valuation class, the system deletes the previous G/L account and prompts you to enter a G/L account. If you cancel the account assignment screen and change the material group back on the item detail screen, the previously determined G/L account is not determined again. Why is this?

Answer:

Unfortunately, this system behavior cannot be changed. First, enter any G/L account, so that the item is valid. If you then switch to the old material group again, the system also determines the correct G/L account again.

--------------------------

4. Question:

Is there an easy way of entering the same account assignments for different items in the new EnjoySAP transactions?

Answer:

Ensure that Note 315676 has been implemented in your system and follow the procedure described there.

--------------------------

5. Question:

Why does the repeat account assignment function not work in the new EnjoySAP transactions when you create new account assignments in multiple account assignment?

Solution:

Use the copy function in multiple account assignment to create identical account assignment lines. You can use the repeat account assignment function to create similar account assignments for different items with the same account assignment category. To do this, proceed as described in the answer to question 4.

--------------------------

6. Question:

When you change the account assignment of an existing purchase order, why does the system issue message KI 161: "Cost center &/& does not exist on &" ?

The same phenomenon occurs for other account assignment objects (for example, profit center).

Solution:

Refer to Note 193371.

--------------------------

7. Question:

Can you create assets from the single account assignment screen?

Solution:

Assets can only be created from the multiple account assignment screen ("Account assignment" tab).

You can switch between single account assignment and multiple account assignment on the "Account assignment" tab page by clicking the icon above on the left.

--------------------------

8. Question:

Why does the system not display an account assignment tab page even though you have entered an account assignment category?

Solution:

After you have implemented Note 520149, the account assignment tab is not displayed until all the required information is available, for example, the company code.

--------------------------

9. Question:

Why are account assignment objects derived in some situations, even though the relevant field on the account assignment tab page is hidden?

Solution:

Refer to Note 619203.

--------------------------

10. Question:

You create a purchase order with reference to a subcontracting purchase requisition. This purchase requisition was created with an unknown account assignment, that is, account assignment category "U". When you change the account assignment category in the purchase order, the system issues error message ME 453 "Changing consump. or spec. stock indicator not allowed (subcontracting)".

Solution:

See Note 205597.

--------------------------

11. Question:

Why can you not select a valuated goods receipt together with multiple account assignment in a purchase order or purchase requisition?

Solution:

See Note 204252.

--------------------------

12. Question:

Funds Management is active. Why are the fields EBAN-FISTL, -GEBER, -KBLNR, -GRANT and -FKBER (as in table EKPO) empty?

Solution:

These fields are only filled if the account assignment category is set to "blank". If you maintain an account assignment category in the purchasing document, the system adds the information from these fields to the EBKN table (as in EKKN).

--------------------------

13. Question:

You try to change a purchase order item with account assignment category "A", which contains a locked asset. The system issues error message AA 334 "You cannot post to this asset (Asset & & blocked for acquisitions)".

Solution:

This is the standard system design. To make changes to this purchase order item, you have the following two options:

a) If you no longer require the purchase order item with the blocked asset, delete the purchase order item.

b) Otherwise, you must activate the asset, make the required changes to the purchase order item, and then block the asset again.

--------------------------

14. Question:

What is the meaning of the indicator for the account assignment screen that you can set in Customizing for single and multiple account assignment?

Solution:

The indicator determines which account assignment screen is used by default for maintaining the account assignment for a purchase order item.

For the EnjoySAP transactions, this value is simply a proposal that you can change in the purchasing document.

For the old transactions, this value is the only one that you can use.

--------------------------

15. Question:

Is there an unknown account assignment for standard purchase orders?

Solution:

This is generally not allowed, and the system issues message ME 069 "Unknown account assignment not defined for use here". There is an exception in the case of service items that are created with item category D (service) or B (limit).

--------------------------

16. Question:

You change data in a purchase order item (for example, purchase order value, delivery date, and so on). Why does the system not perform another account assignment check?

Solution:

This is the standard system design. When you created the purchase order item, if the system already checked the account assignment and there were no errors, another account assignment check only takes place if you change a field that is relevant to account assignment (for example, quantity, material number, and so on).

If this system response does not meet your requirements, implement the account assignment check in the BAdI ME_PROCESS_PO_CUST. The BAdI is called each time the purchase order is changed.

--------------------------

17. Question:

If you delete all the account assignment lines that were entered in the account assignment screen, the system exits the account assignment tab page and goes to the material data. In addition, the system issues the error message "In case of account assignment, please enter acc. assignment data for item".

Answer:

In the current system design, if you delete all the account assignment lines, the system assumes that you do not want to maintain any account assignment data.

This conflicts with the account assignment category and the system issues error message 06 436.

You can then remove the account assignment indicator.

Procedure:

If you want to delete all the account assignment data that was entered, see the answer to question 24.

--------------------------

18. Question:

Which account assignment categories should you enter in schedule line categories for third-party order processing (CS) and individual purchase order processing (CB)?

Solution:

See Note 210997.

--------------------------

19. Question:

In a blanket purchase order or blanket purchase requisition with account assignment, you subsequently change the material group. Even though the new material group is assigned to another G/L account via the valuation class, the system does not redetermine the account assignment for the relevant item. The old G/L account remains.

Solution:

See Note 449216.

--------------------------

20. Question:

In Customizing, you can set the account assignment fields as required fields, optional fields or display fields, or as completely hidden fields, depending on the account assignment category. These settings also determine whether the system deletes or retains the values for the account assignment fields when you change the account assignment category in a purchase order item.

Answer:

In Customizing for materials management (MM), when you maintain account assignment categories (IMG: Materials Management-> Purchasing -> Account Assignment-> Maintain Account Assignment Categories), you can control the different account assignment fields as follows:

Required entry: You must make an entry in the field, otherwise the system issues error message ME 083.

Optional entry: Entry in this field is optional.

Display: The field is displayed, but it is not ready for input.

Hidden: The field is hidden.

Example:

The account assignment category is K, the cost center is an optional entry field and it is filled with the value 1000.

You change the account assignment category to P.

Subject to the field settings for the cost center for the account assignment category P, the system response is as follows:

Cost center required entry or optional entry: the value 1000 for the cost center is transferred

First, the value 1000 for the cost center is deleted. If the system can determine a value again after you enter the changed account assignment category, this value is transferred.

The system deletes the value 1000 for the cost center.

--------------------------

21. Question:

You create a purchase order item assigned to an account with reference to a purchase requisition. For this purchase order item, you create a second schedule line with reference to another purchase requisition. The system ignores the account assignment data of the purchase requisition for the second schedule line.

Solution:

This is the standard system design. The system does not generate multiple account assignment in the purchase order item, even if the two referenced purchase requisitions are assigned to different CO objects.

Refer to Note 47150 for the old transactions and to Notes 422609 and 771045 for the EnjoySAP transactions.

--------------------------

22. Question:

Why can you undelete an item in a purchase requisition if

the corresponding account assignment data is no longer valid?

Solution:

When you undelete an item in a purchase requisition, the system does not perform a new account assignment check. Therefore, the account assignment data is not checked again.

Nevertheless, errors occur if you try to create a purchase order with reference to this purchase requisition.

When you undelete an item in a purchase order, however, the system does

perform another account assignment check.

--------------------------

23. Question:

You create a purchasing document with reference to a reference document. What account assignment data is transferred?

Solution:

The account assignment data is derived from the reference document.

If you delete the account assignment category and enter it again, a new automatic general ledger account determination takes place.

--------------------------

24. Question:

What is the correct procedure for changing account assignment data?

Solution:

- If, for example, you want to change the account assignment category:

Note that you MUST first delete all existing account assignment data for the relevant item.

You can do this by initializing (deleting) the account assignment category and confirming by choosing ENTER.

Following this, you can enter the new account assignment category and the relevant account assignment data.

- If you want to change account assignment data for the relevant item;

For example, you want to change the main account assignment objects such as cost center, G/L account, sales order, network, or WBS element, and so on. Here also, we recommend deleting all existing account assignment data by initializing (deleting) the account assignment category and confirming by choosing ENTER.

If you are working with contracts, you must delete the account assignment line on the account assignment screen and enter a new line to ensure that the data is derived correctly again.

Customizing should not be changed during operation!

For example, in some circumstances, the requirements type (OVZH) or the valuation of the requirements class (OVZG) is changed after the purchasing document is created. This can cause errors in a valuation of goods movements (goods receipt, for example) and MUST BE AVOIDED.

--------------------------

25. Question:

For a purchase requisition (PReq), can I use BAPI_PR_CHANGE to switch from multiple to single account assignment by deleting all account assignments but one?

Solution:

This is possible. In the first step, you must use BAPI_PR_CHANGE to deselect the quantity at item level (EBAN-MENGE) to the quantity°of the remaining account assignment line to be set. At the same time, all other account assignment lines except the one required are deleted.

Due to technical BAPI properties, the distribution indicator for multiple account assignment (EBAN-VRTKZ) must only then be adjusted using a second BAPI_PR_CHANGE run°and set to "Single Account Assignment" (this is also possible interactively using transaction ME52N).

It is not possible to perform both steps within a single BAPI run.

Price variance

When processing a purchase order, the system checks whether the effective price of a PO item shows variances compared with the valuation price stored in the material master record. In addition, it checks whether the specified cash discount value is admissible.Variances are allowed within the framework of tolerance limits. If a variance exceeds a tolerance limit, the system issues a warning or error message.

PE Price variance, Purchasing

◦Tolerance limit for system message no. 207. This message appears if the specified effective price exceeds the predefined tolerances when compared with the material price.

SE Maximum cash discount deduction, Purchasing

◦Tolerance limit for system message no. 231. This is a warning message, which appears when the specified cash discount percentage exceeds the predefined tolerances.

You can specify whether the system message appears as a warning or error message using the menu options Environment -> Define Attributes of System Messages.

Effective price

- To be able to compare the effective price determined in the purchase order with the material price in the material master, the effective price is converted into the base unit of measure and price unit measure stored in the material master.

- The current price (for example, standard price, moving average price) in the material master, and

- The price unit in the material master

Scheduling Agreement

References

As reference document (the document you copy from), you can use:- Purchase requisitions

- RFQs/quotations

- Other scheduling agreements

- Centrally Agreed Contracts

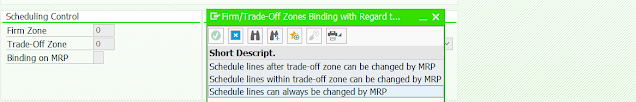

Defining the Firm, Trade-Off, and Planning Zones

- Firm zone (zone 1) (go-ahead for production).

- The schedule lines within this zone count as firm and thus as fully binding. If you cancel a schedule line that falls within the firm zone, the vendor is entitled to charge you with both production costs and the costs of procuring input materials incurred by him as a result of the cancellation.

- Trade-off zone (zone 2) (go-ahead for procurement of input materials)

- This is the "semi-firm" zone, giving the vendor the go-ahead to procure necessary input materials to manufacture the item ordered. If you cancel a schedule line within this semi-firm zone, the vendor is only entitled to charge you the material costs. Schedule lines falling within this time zone are thus less binding that those falling within the firm zone.

- Planning zone (zone 3) (forecast)

- All schedule lines that lie beyond the first two zones (that is, delivery is tentatively scheduled for quite a long way into the future) fall within the planning zone.

- The firm and trade-off zones are printed out in the schedule for the user’s information.

Scheduling Agreement Releases

Scheduling agreement releases provide information to vendors regarding the quantities of a material that are to be delivered and the desired delivery dates.Material requirements planning

The current overall delivery schedule for a material that is procured via scheduling agreement releases changes continuously during an MRP run due to the requirements for that material. The schedule lines created by the MRP run are assigned creation indicator 'B' and are contained in table EKET in field ESTKZ, manually created -'R'.

Release generation (FRC/JIT)

There is no release documentation for stock transport scheduling agreements.- Forecast delivery schedule (FRC)

- Provides the vendor with information over the longer term about which quantities of a material are to be delivered on which date. Delivery dates are usually specified as calendar months or weeks.

- ”planning schedule with release capability” (ANSI 830) ”delivery schedule (message)” (EDIFACT DELFOR), and ”delivery instruction” (ODETTE DELINS).

- JIT delivery schedule (JIT)

- Provides the vendor with information about which quantities of a material are to be delivered at which point in time in the near future. Exact delivery dates (calendar days) or even delivery times are usually specified.

- ”JIT delivery schedule” are: ”Shipping schedule”: (ANSI 862) and ”Delivery just in time message” (EDIFACT DELJIT).

- EKET - schedule lines (created by MRP, manual, BANF)

- EKEH - schedule lines of the delivery schedule

- EKEK - header data of all delivery schedules

- EKPO - item data of the purchasing documents

Creation Profile

- Under which conditions, the system creates a release of this type (Creation strategy)

- Whether backlogs (Quantities with a delivery date in the past that were transmitted to the vendor by means of a scheduling agreement release, but which have not yet been delivered) and immediate requirements are to be calculated and identified.

- In the 'Aggregation horizons' area, you specify for each release type which time horizon the system uses to determine release quantities and for which periods the system aggregates the quantities to 'period quantities', where applicable.

- Example:

The profile set to aggregate requirements with the planning calendar ( weekly, on Tuesday during 20 days )

The following deliveries were added manually:

As a result, within 20 days the requirements are aggregated according to the profile, and afterward monthly

- In the 'Creation Periodicity' area, you specify for each release type if, and if so, at what intervals, the system is to create a release of that type.

- Every time that the system creates a release, it calculates the next transmission date for periodic transmission based on the date.

- In the 'Tolerance Profile' area, you specify for each release type if the system checks by how much the current release to be created differ from the last release transmitted, and if so, how it carries out this check.

Function modules

- ME_CREATE_SCHEDULE_DOC - Creates FRC and JIT delivery schedules

- ME_CHECK_TOLERANCE

- ME_UPDATE_FROM_PRINTING - makes an update to the print relevant data

- ME_UPDATE_SCHEDULE_EKPO - update of the next transmission date

- ME_READ_LAST_RELEASE

- ME_COMPARE_SCHEDULES

Routines (SAPLEINL) called from ME_CREATE_SCHEDULE_DOC

- ANALYSE_PROFIL - analyses transmission profil regarding periodicity

- BESTIMMEN_ABRUF_NR - determines release number

- FUELLEN_KOPF - creates new EKEK records

- FUELLEN_EINTEILUNGEN_NEU - creates new EKEH records regarding ameng (without Release Creation Profile)

- AGGREGIEREN_EINTEILUNGEN_NEU - aggregates schedule lines

Output/Transmission of release

- LPH1 for FRC; updates data relevant for printing

- LPJ1 for FAB; updates data relevant for printing

- LPET for conventional scheduling agreements without release documentation

- LPMA for scheduling agreement expediters

Administer

Outline Agreement Scheduling Agreement Administer:

- Re-number Schedule Lines

- Aggregate schedule lines

- Aggregate order history

- Remove Scheduling Agreement Releases

Cumulative Quantities

The cumulative quantity represents the total quantity that has been delivered to date after each delivery of a scheduled quantity.Path:

- Select the desired item in the item overview when changing a scheduling agreement.

- Enter the date of agreement in the Reconciliation date field on the Additional data screen. Then enter the agreed quantity in the Agreed cum. qty. field.

Centrally agreed contracts

- A single purchasing organization procures for an entire corporate group, or

- A reference purchasing organization makes a contract available to other associated purchasing organizations, enabling the latter to issue release orders against this contract

Centrally Agreed Contracts are created in same transaction ME31K, but here is some difference in maintaining the pricing conditions and partner functions.

Maintaining Plant Conditions

1. When maintaining the centrally agreed contract, choose Edit > Plant conditions > Overview.2. On the overview screen that then appears, enter the desired plant and choose "Overview" icon Plant prices.

3. An item overview screen appears, starting from which you can maintain conditions.

Choose Item > Conditions to access the condition maintenance screen.

4. Return to the overview and repeat the process for all plants for which you wish to store plant-specific conditions.

5. Save your input.

Maintaining Partners

You can maintain the different partners either in the vendor master record or individually in the contract. If the partners have been maintained in the vendor master, they are suggested in the contract.Maintaining partners in a contract

1. In the contract, choose Header > Partners.2. The Data Retention Level: Partners screen appears. Enter the plant and/or vendor sub-range, and choose ENTER. The Maintain Partners screen appears.

Note: To see which partners have already been maintained, select the desired item and choose "Display" button Level.

3. Enter the desired partner and return to the item overview for the contract.

4. Save your input.

Maintaining partners in the vendor master

1. Choose Extras > Different data on the Partner Roles (partner functions) screen in the vendor master record.2. On the Create Different Data screen, enter the plant or vendor sub-range and select Partner Roles.

3. Click "Enter" button. The Change Vendor: Partner Roles screen appears.

4. Enter the desired partners and click "SAVE" button to save your input.

Then create Release orders (in ME21N) w.r.t. Centrally Agreed Contract.

Processes

Direct procurement

Direct procurement also is the place for automation as due to high volumes, predictability, and long lead times.

# 2 Contract and Source Determination

Prioritization is in descending order:

- Production versions (in-house)

- Delivery schedules (external)

- Purchasing contracts (external)

- Purchasing info records (external)

- ANZE Display Purchasing Info Record

- ME11 Create Purchasing Info Record

- ME12 Change Purchasing Info Record

- ME13 Display Purchasing Info Record

- Source list (available as of SAP S/4HANA OP 1709)

- The source list specifies suppliers for a material by time period ( as fixed (preferred), planning (used for MRP), or blocked ).

- Scheduling agreement ( customizing: plant parameters and the MRP group parameters (! prioritized )

- S4 apps: Manage Scheduling Agreements, Mass Changes to Scheduling Agreements, Manage Workflows for Scheduling Agreements

- Procurement types:

- Subcontracting, which can specify when components are to be delivered to the subcontractor for assembly/work for each scheduled line item

- Consignment, for scenarios in which the supplier only invoices after consumption of provided stock on-premise at customer

- Stock transfer, for internal orders of items from other plants/warehouses

- Quota arrangement ( MEQ*)

- to be supplied from several vendors

#3 MRP run

MRP run then generates a schedule line in a scheduling agreement, a sourced requisition, or an unsourced requisition.#4 PO creation

Automatic PO creationProcurement optimization

Improve performance and reduce process costs in procurement and supply chain management. In the SAP system, the sources are referred to in the planning procedure to generate procurement proposals. Sources provide the material or service to achieve KPIs of the business.

Use cases:

- Source Determination

- Source Determination with SAP E-Sourcing

- Optimizing the Order Quantity

- Creating Purchase Orders with Source Determination

- Collecting purchase requisitions to a purchase order (ME59N)

- Purchase document type determination (business rules)

Source Determination

A source can be determined through the steps (ECC):

- Quota arrangement

- Source list ( If several sources are found, a box appears for selection purposes )

- Contracts, scheduling agreements, and info records

- When an info record is found

- The system checks whether a certain supply region is specified in the associated vendor master record. If so, the system checks whether the plant in the purchase requisition belongs to this region.

- Check of regular vendor

+ Simplified Sourcing Approach (S4)

- The Info-record is considered as a single element to determine the source.

- The source list use is limited to temporary block/enable the vendor for procurement.

Sourcing selects valid sources of supply with the following conditions:

Quota arrangements can be used to prioritize sources of supply in case several sources of supply are valid simultaneously.

- The source of supply is a production version

- and the procurement type of the material is either 'E' (in-house production) or 'X' (Both procurement types)

- and the production version is neither "Locked for any usage" nor "Locked for automatic sourcing"

- and the planned material receipt's quantity is inside the quantity range of the production version

- and the planned material receipt's delivery date is in the validity period of the production version

- The source of supply is a purchasing info record

- and the procurement type is 'F' (external procurement)

- and the purchasing info record is flagged for "Relevant for automatic sourcing"

- and the planned material receipt's quantity is inside the quantity range of the purchasing info record

- and the planned material receipt's delivery date is in the validity period of the purchasing info record

- The source of supply is a delivery schedule and the procurement type is 'F' (external procurement)

- The source of supply is a purchasing contract and the procurement type is 'F' (external procurement)

Quota arrangements can be used to prioritize sources of supply in case several sources of supply are valid simultaneously.

If sourcing determines several valid sources of supply for the same material, plant, quantity, and date, but does not find any quota arrangements, then it prefers:

- production versions over delivery schedules,

- delivery schedules over purchasing contracts,

- and purchasing contracts over purchasing info records.

If sourcing selects a production version as a source of supply, then the material receipt is going to be a planned order. If sourcing selects a purchasing info record, then the planned material receipt is going to be a purchase requisition.

When the source of supply like schedule agreement, contracts, and info records are maintained, a CDS view (table view: CDS_M_PUR_SOS_B) is created and field: PRIORITY is updated with priority for selection of source in MRP live run. In MRP live run will select the appropriate source of supply based on priority number 1 to 12. (Refer SAP note: 2614920).

The user in the e-sourcing system controls how the related purchasing documents are created in the ERP system after completion of the award for the e-sourcing request for proposal (RFP).

If we enter a minimum order quantity in the purchasing info record, the PO quantity will be rounded up to the desired minimum quantity after evaluation of the rounding profile where appropriate.

When working with scheduling agreements, you can only use static rounding profiles.

Source Determination with SAP E-Sourcing On-Demand Solution

Requests for quotations are only sent to the e-sourcing system if the vendor in the header data of the RFQ is the vendor that is defined in Customizing for e-sourcing.The user in the e-sourcing system controls how the related purchasing documents are created in the ERP system after completion of the award for the e-sourcing request for proposal (RFP).

Optimizing the Order Quantity

Round off order quantities in POs and contract release orders.

Rounding happens based on profile:

- Static rounding profile

- Quantity addition/subtraction

- Dynamic rounding profile

When working with scheduling agreements, you can only use static rounding profiles.

- Before rounding can take place, we must enter the rounding profile in the scheduling agreement and have previously created a source list record flagged as MRP-relevant with automatic schedule line generation for the scheduling agreement.

Creating Purchase Orders with Source Determination

The system suggests possible sources of supply for the material on the basis of existing quota arrangements, source list records, outline agreements, and/or info records.- Select the Source determination field if the source is to be determined automatically and assigned to a PO item after entry of the latter during manual creation.

Collecting purchase requisitions to a purchase order (ME59N)

Preconditions for successful automatic processing are

- sources are available for all items and

- the system can identify just one source for the requested materials or services out of several possible ones (on the basis of source list entries, the designation of "regular vendors, and use of quota arrangements).

- The system selects only those requisitions for automatic PO generation for which the indicator Automatic purchase order has been set for both the material and the vendor.

If we only have a few sources in your system, manual processing is advisable.

Purchase document type determination (business rules)

Report RM06BB30, transaction ME59NPurchase requisitions with different document types cannot be converted to purchase orders.

- If the document type of the purchase requisition differs from the document type of the purchase order, the system considers the default document type (for transaction ME21) for the determination.

- If we choose the selection "Per item category", the system determines the order document type using the table T161A. If there are several allowed document types, the document type that is entered in the first position for the relevant selection in the table T161A has priority.

Stock transport orders and the purchase order split for each item category are special cases:

For stock transport orders, the document type is derived from the supplying plant/receiving plant combination (table T161W or Customizing transaction OMGN).

- If the purchase order split is active for each item category, the item category is also used during the document type determination:

- If there is one purchase order document type that is identical to the purchase requisition document type and the same item category is allowed like the one in the purchase requisition (according to table T161A), the system uses this combination.

- If there are several possibilities, the system selects the first document type for which the same item category is allowed for the purchase requisition.

- If this does not succeed (as in the general case), the same document type (if available) is chosen (but with a different item category) or the default document type for transaction ME21 or the first allowed one.

References:

- 114213 - ME59: Determining the order document type

- 2268069

Control parameter determination

Confirmation control key determination

Normal PO items (not returns items)

- If goods receipt is already posted for the PO item or if there are existing confirmation entries, the determination is not executed.

- If the PO item is created by referencing another PO item (meaning an existing PO is copied), the confirmation control key (CCK) is simply copied from the referenced item.

- If the PO item is not created by referencing another PO, but it has a reference to a contract, the system takes the CCK of the contract (even if the CCK is blank).

- One exception is if the contract has the item category "material group" or "material unknown". In that case the CCK is taken over only if it is not blank.

- If the PO is not created with reference to a contract, the system looks up in the info record. If one is found, the system takes the CCK from the info record.

- If both a contract and an info record are referenced, the system always takes the CCK of the contract, even if it is blank.

- If the PO has no contract and no info record, the system takes the CCK of the vendor master data (LFM1-BSTAE).

- If there is alternative vendor master data (e.g. plants-specific, or vendor subrange in table LFM2), then the CCK is taken from there.

- If the PO has a contract or info record reference, the CCK will be taken from those and not the vendor master even if it is blank in the contract / info record.

This behavior can be changed by implementing the modification note 909885: the system will take the CCK from the vendor master if it is blank in the info record.

In ME21N, ME22N, ME59N, BAPI_PO_CREATE1 and BAPI_PO_CHANGE we can use BADI ME_PROCESS_PO_CUST to introduce your own logic and derive from the standard one.

Returns PO items

- If goods receipt is already posted for the PO item or if there are existing confirmation entries, the determination is not executed.

- The use of a CCK is generally not allowed in returns PO items. It is allowed only in a special case, if Advanced Returns Management is used (business function OPS_ADVRETURNS_1 is activated). If it is active and the Enhanced Store returns is also activated for the PO document type (T161-FLS_RSTO=X) and the PO has a supplying plant (EKKO-RESWK) or a vendor that is assigned to a plant (LFA1-WERKS is not blank), only then it is possible to use a CCK.

- If these conditions are met, the system checks if the PO is created by referencing another PO for which the Enhanced Store returns is also active. If such a PO is used as reference, the CCK is taken over from that.

- If no such PO is used, the system proceeds to read the T163LV for a CCK with the same logic as in case of non-returns items above.

- In case of returns items, the contract, info record and vendor master are not checked, only the reference PO and the T163LV.

- If no CCK is found based on T163LV, a manual entry is possible.

- In ME21N, ME22N, ME59N, BAPI_PO_CREATE1 and BAPI_PO_CHANGE you can use BADI ME_PROCESS_PO_CUST to introduce your own logic and derive from the standard one.

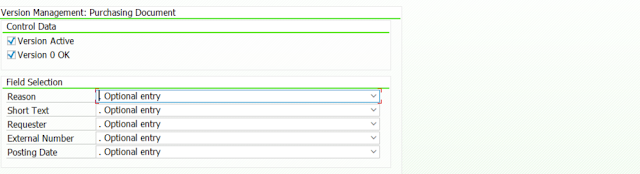

Version management

When?

In the case of procurement transactions extending over a longer period of time , we might need to differentiate between various versions of the purchasing document.

What?

Version Management enables us to generate and manage versions of purchase requisitions and external purchasing documents. If we are using version management, the system also manages the texts that are included in the versions.

Where?

Version management can be used in connection with purchase requisitions (ME51N, ME52N and ME53N only), RFQs, purchase orders, contracts, and scheduling agreements.

What is the trigger for a new version?

What is the trigger for a new version?

The system always creates a new version when the purchasing document has reached a final state.

Not every change to an external purchasing document results in a new version. Only the following changes lead to a new version:

Q: How to carry out mass Change in PO when version management is active?

A: BAPI_PO_CHANGE contains the version fields in the import structure

Q: What is the table for version management?

A: EREV Version in Purchasing

In the case of procurement transactions extending over a longer period of time , we might need to differentiate between various versions of the purchasing document.

What?

Version Management enables us to generate and manage versions of purchase requisitions and external purchasing documents. If we are using version management, the system also manages the texts that are included in the versions.

Where?

Version management can be used in connection with purchase requisitions (ME51N, ME52N and ME53N only), RFQs, purchase orders, contracts, and scheduling agreements.

What is the trigger for a new version?

What is the trigger for a new version?

The system always creates a new version when the purchasing document has reached a final state.

- This means one of the following processing states:

- Active: If you do not use the document release functionality

- Release completed: If you use the document release functionality

Not every change to an external purchasing document results in a new version. Only the following changes lead to a new version:

- We can define which changes are print relevant in Customizing for Purchasing under Messages Fields Relevant to Printouts of Changes.

- Changes in document assignment

- Changes in address

- Changes to master conditions

- The purchase requisition be released or converted into a follow-on document

- The external purchasing document be released or output (printed out or transmitted, for example, as a fax or EDI message)

Configuration?

SPRO: Materials Management>PurchasingVersion Management>Set Up Version Management for External Purchasing Documents

SPRO: Materials Management>PurchasingVersion Management>Set Up Version Management for External Purchasing Documents

FAQ

Q: How to carry out mass Change in PO when version management is active?

A: BAPI_PO_CHANGE contains the version fields in the import structure

Q: What is the table for version management?

A: EREV Version in Purchasing

Additional information

459350 - FAQ: Partner determination in purchasing

1. Question:

Why are partners not determined from the vendor master/contract/reference when a purchasing document is created (purchase order, request for quotation, contract, scheduling agreement)?

Answer:

See SAP Notes 37170, 394091, 376319 (for transaction ME21N), and 673062.

--------------------------

2. Question:

Why are partners determined for another purchasing organization during the creation of a contract?

Answer:

You create a purchasing contract, for example, for purchasing organization A. In the vendor master, several partners are maintained for the vendor for purchasing organization A. In addition, several partners are maintained for the vendor for purchasing organization B.

In transaction OMKJ, purchasing organization B is assigned as a reference purchasing organization to purchasing organization A.

In the detail for this assignment, the vendor master indicator is set. This indicator enables access to the info record of the reference purchasing organization. As a result, partner determination also determines partners for reference purchasing organization B. Please note that this function can only be used in an IS Retail system (provided the switch ISR_RETAILSWITCH is active)!

This function cannot be used for NON IS Retail systems.

--------------------------

3. Question:

Why are the partners not displayed when you display a purchasing document even though the corresponding entries exist in the table EKPA? (Transfer of documents from legacy system during release upgrade).

Answer:

Check whether the field EKORG (purchasing organization) is blank in the table EKPA for the entries for the purchasing document. If this is the case, you can use the report Z_CORR_EKPA to correct the inconsistencies.

You can obtain this report from SAP Support.

--------------------------

4. Question:

Why are no partners determined and why do manually maintained partners disappear for a stock transport order or stock transport scheduling agreement?

Answer:

See SAP Notes 117537 and 401734.

--------------------------

5. Question:

Why does the system issue error message ME 266 ("Mandatory roles missing") in transaction ME21N even though in Customizing, no partner schema is assigned to the document type, so that partner determination does not take place?

Answer:

See SAP Note 420058.

--------------------------

6. Question:

Why is partner determination not carried out again in transaction ME22N after you change partner-relevant data such as vendor, purchasing organization and contract (with contract reference)?

Answer:

See SAP Note 431351.

--------------------------

7. Question:

Why are partners not determined when you create a purchase order using transaction ME59(n)?

Answer:

In the vendor master, several entries are maintained for one partner role. If none of these entries is flagged as "default", none of these partners is copied to the document during purchase order generation in transaction ME59(n).

However, if you use transaction ME21 or ME21N to create a purchase order, a dialog box for the selection of a partner is displayed.

--------------------------

8. Question:

Why are partners that have a block or a deletion flag for the client or the purchasing organization not used when you create a purchasing document?

Answer:

See SAP Notes 673062, 563677, 743414, 938652, and 1446971.

--------------------------

9. Question:

You create a purchase order and you manually maintain several partners. Why are the manual partners overwritten when you enter the plant?

Answer:

After you implement SAP Note 761614, a new partner determination is performed if the plant is changed. This is necessary because a change of plant can result in a change of the partners. The system cannot distinguish between partners that are manually maintained and partners that are determined by the system. You must maintain the manual partners at the end of the document creation process.

--------------------------

10. Question:

Why is the invoicing party not determined when you create a purchasing document?

Answer:

See SAP Notes 938652, 1446971 and 1727168.

------------------------------

11. Question:

Which partner roles are taken into account when you create a purchase order and different partner data is maintained for the plant in the vendor master?

Answer:

If the purchase order is to procure for several plants, the partner role for the plant of the first purchase order item is taken into account.

For example, the partner role GS (goods supplier) is different in each plant. However, GS can only be entered once (ME 359).

Solution: Create purchase order items for one plant.

SAP Note: 1360549 JIT/FDS: Incorrect last GR date in delivery schedule

SAP Note: 1309001 Incorrect date for last goods receipt in sched. Agreement

SAP Note: 1263278 ME84: No selection with MPR controller in MRP area

365604 - FAQ: Release strategies in purchasing

Settings in Customizing

a) Release group:

You are only allowed to use one class for each release object (1=PReq, 2=Purchase order). When you use the overall release (as of Release 4.0A), you are only allowed to use one class for the overall release or individual release. Overall release and individual release is not possible in the same document. If you use overall release for purchase requisitions, this must be specified for the document type in Customizing (indicator for V_T161-GSFRG) and the release group (indicator for V_T16FG-FRGFG). During the overall release, the system takes into account only the characteristics that are identical for all items. If, for example, item 10 of a purchase requisition contains material group 001 and item 20 contains material group 002, the material group is set to BLANK for the strategy determination.

b) Release indicator:

A release strategy must contain at least two release indicators. The first indicator must be defined as blocked and the last release indicator must be defined as released. If this is not the case, the release status is not displayed correctly. If a value is entered in field 'Value changes' (V_161S-TLFAE), the system only checks for value increases.

If you have purchase requisitions from material requirements planning (MRP) (EBAN-ESTKZ = 'B') that are subject to a release strategy, the system may reset a PReq release when the MRP is restarted. In this case, you should set 'Fix for material requirements planning' for the relevant release indicator (V_161S-FIXBP).

c) Release statuses:

A release indicator must be assigned to each release status that is theoretically possible. Thus, for example for five release codes that can be released in any sequence, you have to maintain 32 entries.

Caution: If the release strategy contains many release codes, the system does not display all the statuses in the window. In order to display these release statuses, you have to use the page down or page up keys on the keyboard since the window has no scroll bar.

2. Settings in the classification

The characteristics of the class used must all be linked to the corresponding fields of structure CEBAN (for purchase requisitions) or CEKKO (for purchase orders).

The characteristics must be entered as they are specified on the database, that is, the item category must be entered in the internal format, for example (value 0-9), cost centers or material numbers must be entered with leading zeros.

If intervals are used for the characteristics, the corresponding characteristic must be marked as multiple value in the classification.

If a characteristic is non-valuated (blank entry), this field must actually be filled with blanks in the document. A blank entry can be useful when the overall release is used. A blank entry is not to be seen as a wildcard (*). If, for example, all material groups of a release strategy should be subject to an update strategy, you must enter these explicitly in the classification. You cannot use a placeholder (wildcard). You can maintain a blank entry as follows:

-Enter the characteristic in transaction CT04 (for releases < 4.6, transaction CT02)- Select 'Value'

Do not maintain any entry in column 'Characteristic value'

In the column 'Characteristic name', enter a text such as, for example, 'Blank entry' and save the settings

The blank entry that is maintained as such can now be selected from the F4 help in Customizing for the release strategy (pushbutton: Classification).